HEAT RECOVERY UNIT - ICOSAVE

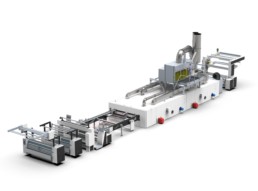

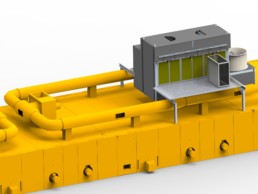

Heat Recovery Unit for Stenters and Dryers - ICOSAVE

HEAT RECOVERY UNITS TO SAVE ENERGY IN STENTERS AND/OR DRYERS OF ALL BRANDS

With our ICOSAVE UNIT we can help you reduce energy costs in your company. Save on the gas consumption of your machine.

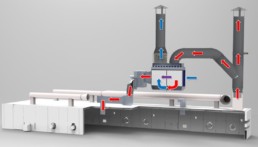

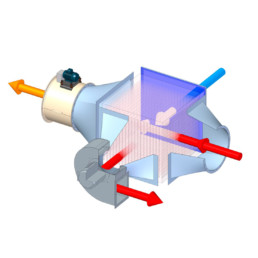

SYSTEM AIR-AIR

The ICOSAVE unit uses the thermal energy from the chimney air to reheat the clean air that will be sent to the stenter with the consequent savings in gas consumption.

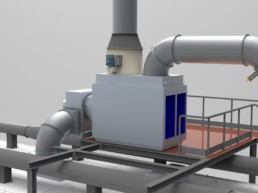

SYSTEM AIR-WATER

Instead of air, the ICOSAVE system will heat water to be used in the dyeing process.

THE ICOSAVE AIR/AIR OR AIR/WATER HEAT RECOVERY FOR STENTERS AND DRYERS UNIT INCLUDES THE FOLLOWING ELEMENTS:

- General construction of the machine in Stainless Steel AISI 304

- Heat exchangers made of aluminium.

- Heat exchanger cleaning system. Our heat recovery system has an integrated automatic washing system applied to the heat exchangers.

- Anti-fire system integrated into the machine. The equipment has a butterfly fire air valve along with a temperature detector placed at the inlet of the unit, in case of excess temperature the valves would be closed and the water / or steam would be opened.

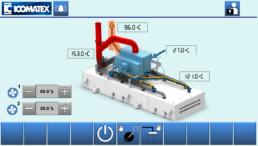

- The unit includes the electrical panel. The electrical cabinet shows the inlet and outlet temperatures, in the cold zone and in the heat recovery zone.

- Tubular structure with pressure doors for easy cleaning and accessibility.